The ladder logic symbols that are used in PLC programming have been derived from traditional relay logic control circuits. If you have a basic knowledge of electric circuits then getting started in ladder logic programming should be a breeze. If not, don’t worry, ladder logic is a graphical programming language and getting to know the basic ladder logic symbols and concepts is quite easy.

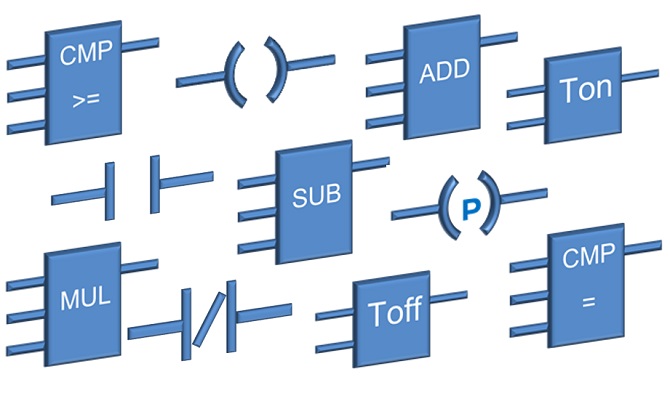

Ladder logic symbols are the fundamental programming components used in ladder diagrams. In PLC programming, ladder logic symbols can be used individually or in combination to create logic instructions. Traditionally, ladder logic symbols were created for bit logic operations, but now include higher level functions such as timers, counters, math, comparison, PID loops, data manipulation and data conversion.

Learning the basic ladder logic symbols will give you a solid foundation. Generally speaking a large majority of real world applications can be accomplished with the basic ladder logic symbols. As your desire to program complex automation and process control Functions increases, then higher level ladder logic symbols can be used like math operations, PID loops, data manipulation and data conversion.

The main symbols for PLC ladder logic are the input symbols and output symbols. Digital inputs are expressed as normally open contact (NO) symbols or normally closed contact (NC) symbols. While digital outputs are expressed as a coil symbol.

In ladder logic the normally open contact (NO) and normally closed contact (NC) symbols are mainly used to define PLC digital inputs and internal logic instructions. They have been translated into ladder logic from switches and relay contacts used in electric circuits.

An coil in ladder logic is the symbol which mainly defines PLC digital outputs. However, a coil can also be used with internal memory in order to trigger internal logic instructions. The coil symbol has been translated into ladder logic from relay coils used in electric circuits.

The NO and NC contacts are some of the fundamental symbols used in PLC programming. Let’s take a more detailed look at them and other symbols used in PLC programming by investigating their operation and how they are commonly used in a ladder diagram….

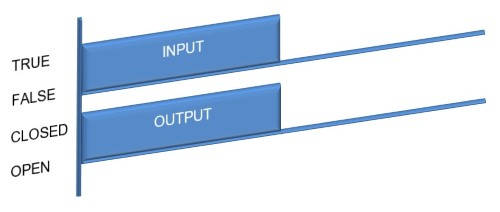

Normally Open Contact (NO) Symbol

Operation:

If the condition is TRUE then the contact is CLOSED and output logic flow is enabled. If the condition is FALSE then the contact is OPEN and output logic flow is blocked.

Common Uses:

- Start Push buttons.

- Selector switches.

- Digital instrumentation.

- Internal programming.

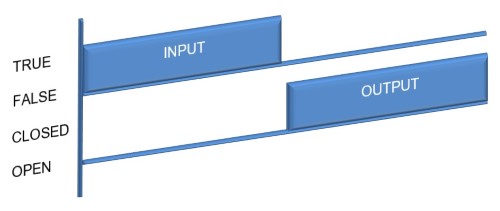

Normally Closed Contact (NC) Symbol

Operation:

If the condition is TRUE then the contact is OPEN and output logic flow is blocked. If the condition is FALSE then the contact is CLOSED and output logic flow is enabled. The NC contact symbol operation is opposite to the NO contact symbol.

Common uses:

- Stop Push buttons.

- Fail safe instrumentation.

- Motor Thermal Overloads.

- Internal programming.

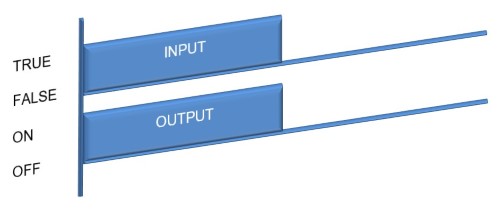

Output Coil Symbol

Operation:

If the input condition is TRUE then the output is ON. If the input condition is FALSE then the output is OFF.

Common uses:

- Motor control.

- Actuator control.

- Indication lamps.

- Warning sirens.

- Internal programming.

- Sequence logic.

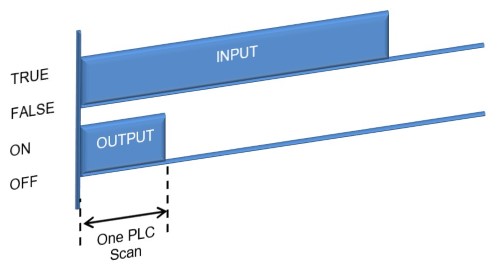

One Shot Symbol– Positive Edge Detection

Operation:

If the input condition transitions from FALSE to TRUE then the output is ON, for the time taken to do one PLC scan.

Common uses:

- Counting applications.

- Math commands.

- Data Transfer commands.

- Latch output during a specific set of conditions.

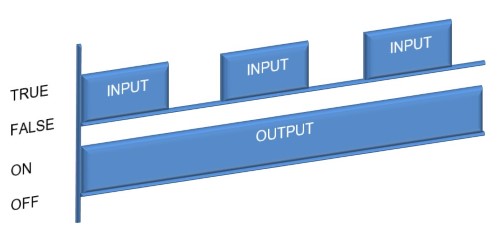

Set Coil Symbol

Operation:

If the input condition transitions from FALSE to TRUE then the output is set ON. Once the output is set ON, it stays ON, even if the input condition goes FALSE.

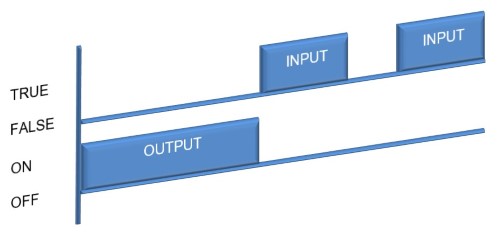

Reset Coil Symbol

Operation:

If the input condition is TRUE then the output is reset to OFF. If the input condition is FALSE it has no effect on the output. The SET and RESET coils can share the same variable address and therefore work hand in hand.

Common uses for Set and Reset Coil Symbols:

- Motor and actuator outputs.

- Indication lamp and warning sirens.

- Internal programming.

- Toggle logic (flip flops).

- Complex latching logic which is set and reset in multiple locations.

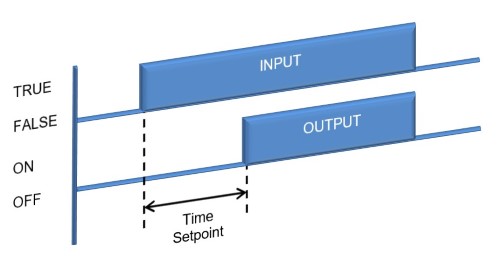

Timer Delay On Symbol

Operation:

If the input condition is TRUE then the timer begins. When the preset time set point has been reached the output turns ON. If the input condition goes FALSE, at any stage, the timer stops and the output turns OFF as well.

Common uses:

- Time delay for Warning Sirens.

- Star/Delta Motor Starters.

- Sequence start delays.

- De-bounce time delay to fix digital instrumentation flicker.

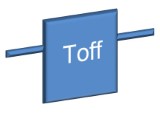

Timer Delay Off Symbol

Operation:

If the input condition is TRUE then the output turns ON. Then if the input condition goes FALSE the timer begins. When the preset time set point has been reached the output turns OFF. If the input condition goes TRUE, at any stage, the timer stops and the output turns ON as well.

Common Uses:

- Cooling Fan run on time delay.

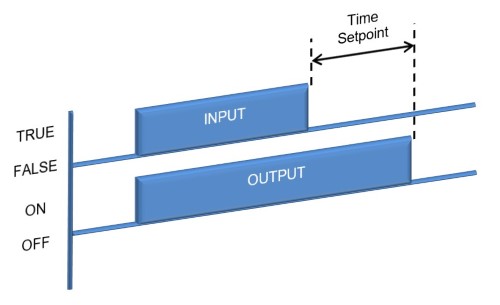

Comparison Symbols

Operation:

If the comparison between two inputs is TRUE then the output turns ON.

Common uses:

- Product Stacking and Un-Stacking complete.

- Batching system weight set point achieved.

- Alarm & Fault activation (Temperature, Flow, Motor Current etc).

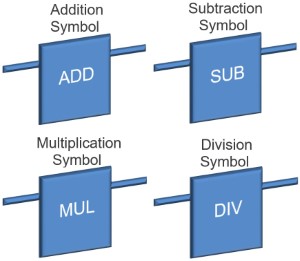

Math Symbols

Operation:

Executes the mathematical operation using the inputs with the result written to the output.

Common uses:

- Scaling of Analogue Inputs and Outputs (Temperature, Flow, Motor Current, Weight, Pressure etc).

- Calculating Motor Speed and Position profiles.

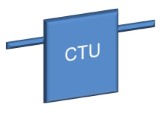

Up Counter

Operation:

If the input condition transitions from FALSE to TRUE then the counter is incremented by a value of 1. The accumulated count value is written to an output. When the count value reaches the preset value the done output is set TRUE. The counter is set back to 0 by triggering the reset input.

Down Counter

Operation:

If the input condition transitions from FALSE to TRUE then the counter is decremented by a value of 1. The accumulated count value is written to an output. When the count value reaches zero the done output is set TRUE. The counter is set back to the preset value by triggering the reset input.

Common uses for Up & Down Counters:

- Counting items for a stacking sequence.

- Counting items for a batching sequence.

- Counting items for a diverting conveying.

- Counting items to be queued in a conveyor line.

- Counting events for alarm and fault triggering.

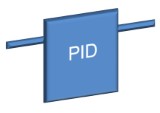

PID Closed Loop Controller

Operation:

The process variable is measured via the input and the output is adjusted to maintain the process variable at the set point input value. The Proportional, Integral and Derivative input values are adjusted to tune the performance of the PID controller.

Common uses:

- Oven Temperature control.

- Irrigation Pressure control.

- Process Flow control.

In the next section were we will fast forward your learning of ladder logic programming by understanding basic operating principles of relay control circuits and also discover the difference between relay logic and ladder logic.

To go to the next section click here.