In this article we’ll look at basic PLC architecture, the different types of PLCs used in industrial automation, advantages and disadvantages of PLC types and compare them in a handy reference table.

What Is PLC Architecture?

The term PLC architecture refers to the design specification of the various PLC hardware and software components and the how they interact with one another to form the overall PLC system. The architecture of a PLC is based on the same principles of that used in standard computer architecture. However, PLC architecture does differ because the design is based around providing high reliability, immunity to harsh industrial environment, ease of maintenance and access to large amounts of peripheral inputs and outputs.

If a PLC system is described as having closed architecture it refers to a proprietary system of hardware and software components that cannot (or is difficult to) connect to other manufacturers components and software. However if a PLC system is described as having open architecture it refers to the PLC system as having off the shelf components that adhere to a common standard and are easily connected to other manufacturer’s hardware and software components.

The Basics of How PLC Architecture Works

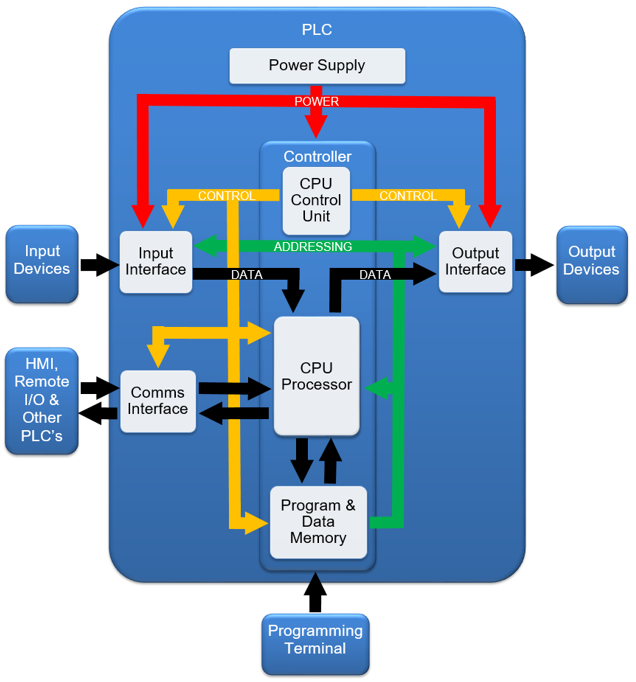

The heart of the PLC system is the CPU (Central Processing Unit). It is made up of a control unit and processor. The CPU control unit manages the interaction between the various PLC hardware components while the CPU processor handles all the number crunching and program (eg ladder logic) execution.

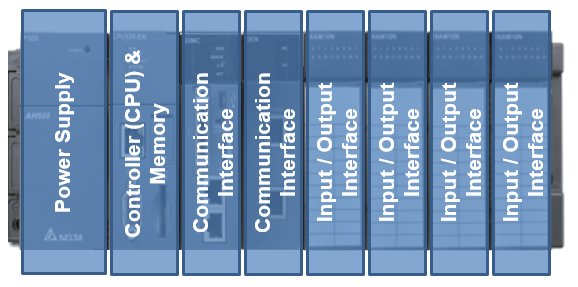

The block diagram below explains the basic architecture of a PLC….

Data flow is from the input devices, through the CPU processor and then to the output devices. The CPU processor also exchanges data with the program and data memory. Once all the data is gathered the program (eg ladder logic) is processed in a cyclic fashion. The resulting data flows to the output interface for conditioning and execution of the output devices.

The CPU also controls and exchanges data with the communication interface and devices.

An addressing system is used for data organization that is shared between the various hardware components.

A programming terminal is used to formulate the PLC program (eg ladder logic), load the program into the controller and monitor/control the PLC and its program.

The power supply is responsible for supplying and managing the power requirements of the various PLC hardware components.

Types of PLC Architecture

PLC architecture has advanced tremendously since its inception of the PLC back in the 1960s. Today the options and variations available to the traditional PLC architecture types is almost endless between different PLC manufacturers.

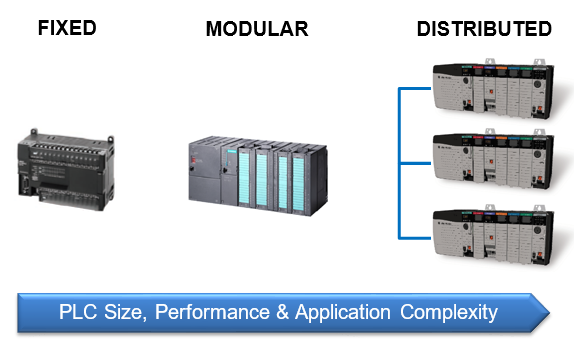

The 3 distinct types of PLC architecture available for use in industrial automation are known as fixed, modular and distributed. The terminology surrounding PLC types can vary between PLC manufacturers, especially when talking about fixed PLCs. There is also crossover between PLC types with some fixed type PLCs having modular type features and some modular type PLCs having distributed type features.

When considering PLC architecture types we can generally say that fixed PLCs are used for smaller sized, less complex application. Modular PLCs are generally used for medium sized, more complex applications. Whereas distributed PLCs are used for large sized, extensive application spread across multiple location.

Let’s take a look at the 3 types of PLCs in more detail….

Fixed PLC Type Architecture

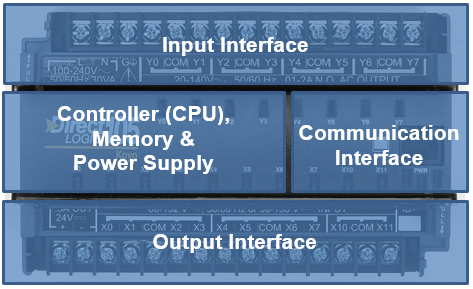

A fixed PLC employs single unit architecture where all the hardware components are embedded into a single unit. Hardware components such as the power supply, CPU, memory, input, output and communication interfaces are all are built into a fixed PLC. The most common names given to fixed PLCs by different manufacturers are fixed, integrated, nano, micro, compact, small, mini, basic, unitary, standard and brick.

Some examples of fixed PLC types by different manufacturers and the terminology they use is shown below:

- Allen Bradley PLC – Micro

- Omron PLC – Compact

- Siemens PLC – Basic

- Delta PLC – Standard

- Koyo PLC – Brick

Regardless of the different terminology that PLC manufacturers use to identify the type, size and performance level of their PLCs, a fixed PLC is universally characterized by:

- PLC naming convention – Fixed, integrated, nano, micro, compact, small, mini, basic, unitary, standard and brick.

- CPU processor – Low powered.

- Program and data memory size – Small.

- Power supply – Embedded.

- Input Interface – Embedded.

- Output Interface – Embedded.

- Communication interface – Embedded.

- Mounting system – Single unit.

- Physical size – Small.

- Flexibility – Input, output and communication interfaces are fixed.

- Expandable – No

- Customizable – No

- Applications – Basic applications with small number of inputs and outputs.

- Cost – Low $$$$$.

Advantages of Fixed PLCs

Fixed PLCs have some great advantages over other types of PLCs. They have been specifically design to cater for smaller, low end automation projects. The advantages of a fixed PLC are:

- Small in size so they do not take up very much space in an enclosure.

- Quick and easy to mount.

- Low in cost so they are an economical solution for basic applications.

Disadvantages of Fixed PLCs

If you’re considering selecting a fixed PLC to automate your next application its prudent to also consider some of disadvantages to make sure you are selecting the type of PLC that is appropriate for your application. The disadvantages of a fixed PLC are:

- CPU processing power is low and memory is small so complex tasks can be difficult to realize.

- Inflexible because the number of input, output and communication interfaces are fixed.

- Only suitable for basic applications with small number of inputs and outputs.

The Modern Day Fixed PLCs

The majority of modern day fixed PLCs are far from what the traditional definition of a fixed PLC is. Technology advancements and demand from industry has driven them away from being a simple, low powered unit with fixed amount of input, output and communication interfaces.

The modern day fixed PLC is feature packed with a large range of options such as powerful CPU’s, expandable modules and network capabilities that are bordering and even overlapping into modular and distributed PLC architecture. This has resulted in the fixed PLC expanding its reach into a larger range of industrial automation applications.

For example the Omron Sysmac CP1L and Koyo DL06 PLCs have traditional fixed PLC architecture but at the same time are expandable with built in slots to allow for extra plugin modules. Another example of a modern day fixed PLC that incorporates modular PLC design is the Delta DVP ES2 with a rack-less design and clip-in expansion I/O modules. The Allen Bradley MicroLogix 1100 PLC range also has the ability to further extend using I/O expansion modules to the side of the PLC using ribbon cable…..

Modular PLC Type Architecture

A modular PLC has a separate module for each of its hardware components. Each PLC module is interconnected using a common mounting system. The mounting system has a certain amount of modules that it can accommodate. This means a modular PLC can be configured to be application specific.

A PLC module is a hardware component that carries out a specific function in accordance to the architecture of the PLC system. The main modules used in a modular type PLC are the processor module, power supply module, input modules, output modules and communication modules. The design of these modules will vary for different manufacturers and usually cannot be interchanged between PLC manufacturers.

Modular PLCs are used for automating industrial applications where a higher powered processor and large numbers of input and output devices are required. These types of applications that use modular PLCs are usually associated with a higher level of complexity with regards to operation, process control and monitoring. Some examples of industries that readily use modular PLCs are manufacturing, food and beverage, mining and logistics.

Some examples of modular PLC types by different manufacturers are shown below:

A modular plc is characterized by:

- PLC naming convention – Modular.

- CPU processor – Medium to High powered.

- Program and data memory size – Medium to Large.

- Power supply – Module.

- Input Interface – Input Module.

- Output Interface – Output Modules.

- Communication interfaces – Communication Modules.

- Mounting system – Rack, backplane, rail or chassis.

- Physical size – Medium to Large.

- Flexibility – High

- Expandable – Yes

- Customizable – Yes

- Applications – Medium to High end applications with large number of inputs and outputs.

- Cost – Medium to high $$$$$.

What are the Advantages of Using a Modular PLC Instead of a Fixed PLC?

Modular PLCs have some great advantages over other fixed PLCs. They have been specifically design to cater for medium to high end automation projects.

The advantages of using a modular PLC instead of a fixed PLC are that modular PLCs have larger memory, higher performance processors, larger number of input and outputs, increased communication options, are fully customizable and are easily expanded. This enables the modular PLC to handle larger scale applications and of higher complexity compared to a fixed PLC.

Modular PLCs also have the ability to have remotely mounted input and output modules (distributed I/O) that are interconnected using a communication link. This allows for increase number of inputs and outputs, reduced cable requirements and installation flexibility.

The modular PLC also has maintenance advantages over fixed PLCs. Each hardware component is separate housed in a module which can be replaced if it is faulty. Whereas a fixed PLC has all its component embedded into a single unit. So when there is a fault the whole unit must be replaced in its entirety and the faulty unit ends up in the trash.

Disadvantages of Modular PLCs

If you’re considering selecting a modular PLC to automate your next application it’s wise to also consider some of disadvantages to make sure you are selecting the most suitable PLC for your application. The disadvantages of modular PLC are:

- Large in size so they take up more space in an enclosure than a fixed PLC.

- The mounting system is more complex than a fixed PLC.

- Higher in cost than a fixed PLC so may not be cost effective for smaller applications.

Distributed PLC Type Architecture

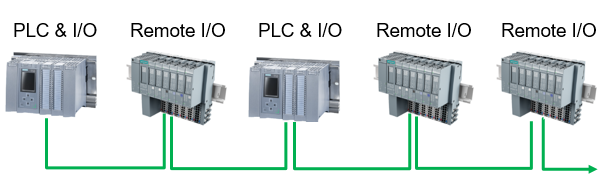

A distributed PLC is a high end PLC system with modular architecture and the capability to interconnect hardware components across different locations via high speed communication links. Each location in the distributed PLC system contains multiple hardware modules that are housed in a mounting system and are usually called a node, rack or drop.

Each drop, node or rack in the Distributed PLC system must have a communication module and can either contain a PLC processor module with input and output (I/O) modules or just I/O modules. When there is a communication module with no PLC processor module and just I/O modules then the node is called distributed I/O or remote I/O.

Distributed PLCs are used for large factories and large processing facilities because they are not limited to physical location. They allow hardware components to be located in different locations by utilizing high speed communication links to interconnect processors and distributed I/O. The distributed PLC type is considered to be a site wide process control solution.

The biggest differences between distributed PLCs and other types of PLCs is that they contain high performance processors, large memories and are able to handle large volumes of I/O, use higher level programming languages and can handle large amounts of complex process control tasks.

In the past a Distributed Control Systems (DCS) was used for large process plants. But the technology driven PLCs of today are performance packed and can handle the heavy demands of a distributed control system.

In today’s world of advanced PLCs most modular PLCs have the features of a distributed PLC. Regardless of the terminology used a distributed PLC is universally characterized by:

- PLC naming convention – Distributed or Modular with Remote I/O.

- CPU processor – High powered.

- Program and data memory size – Large.

- Power supply – Module.

- Input Interface – Input Modules.

- Output Interface – Output Modules.

- Communication interfaces – Communication Modules.

- Mounting system – Rack, backplane, rail or chassis.

- Physical size – Medium to Large.

- Flexibility – High

- Expandable – Yes

- Customizable – Yes

- Applications –High end applications with large number of inputs and outputs.

- Cost –High $$$$$.

What are the Advantages of Using a Distributed PLC?

Distributed PLCs have been designed to process and handle large amounts of data and complex process control. As such they have the following advantages over other PLC types….

- Plant wide control network with multiple processors and remote I/O drops.

- High performance processor.

- Large program and data memory.

- Able to handle large volumes of I/O.

- Can handle large amounts of complex process control tasks.

- Ease of maintenance.

- Save time and money on installation costs.

Disadvantages of Distributed PLCs

Because of the high end features that a distributed PLC has they come with some disadvantages that must be considered when selecting the type of PLC that is required for your automation system….

- Large in size with bigger installation footprint.

- The mounting system is more complex than a fixed PLC.

- Higher in cost than other types of PLC so they may not be cost effective for smaller less complex applications.

- Higher level programming skills may be required.

PLC Types Comparison Table

| PLC TYPES | FIXED PLC | MODULAR PLC | DISTRIBUTED PLC |

| CPU Performance | Low | Medium to High | High |

| Program & Data Memory Size | Small | Medium to Large | Large |

| Power Supply | Embedded | Module | Module |

| Input Interface | Embedded | Modules | Modules |

| Output Interface | Embedded | Modules | Modules |

| Communication Interface | Embedded | Modules | Modules |

| Mounting System | Single Unit | Rack, Back plane, Rail or Chassis. | Rack, Back plane, Rail or Chassis. |

| Physical Size | Small | Medium to Large | Medium to Large |

| Flexibility | No | Yes | Yes |

| Customizable | No | Yes | Yes |

| Applications | Basic applications with small number of inputs and outputs. | Medium to high end applications with large number of inputs and outputs. | High end applications and plant wide control with a very large number of inputs and outputs. |

| Cost | Low $$$$$. | Medium $$$$$. | High $$$$$. |

In the next section we’ll learn about PLC hardware and the essential components that make up a PLC system.

To got to the next section please click here.